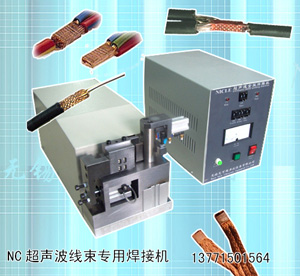

Wuxi Nicole Ultrasonic Equipment Co., Ltd. (13,771,501,564 Liu Xujun) specializing in the production development of Harness Harness welding machine ultrasonic welding machine ultrasonic welding machine dedicated automotive wiring harness multi-strand copper wire welding machine

Ultrasonic welding machine is mainly used for a variety of harness wiring harness welding, using high-frequency ultrasonic vibrations to harness rapid welding, with high efficiency, convenience and low cost.

Uses: Suitable for automotive industry and home appliance industries wire connection.

Welding Principle: Ultrasonic metal welding is the use of high-frequency vibration of the energy generated will be the same species or dissimilar metals, where appropriate under pressure through the cold mill and horizontal movement of surface molecules on the material permeability relative to each other together to achieve the purpose of welding.

Welding advantages: 1, welding material does not melt, non-fragile metal properties. 2, then after the good conductivity and resistivity very low or almost zero. 3 pairs of welding metal surfaces that require low, oxidation or plating can be welded. 4, the welding time is short, without any flux, gas, solder. 5, no welding sparks, environmental protection and safety.

Local advantages: 1, using phase-locked PLL frequency automatic tracking technology, without FM. 2, using the German piezoelectric ceramic transducer. 3, independent intellectual property rights welding head, the world famous brand, lower utility costs. 4, man-machine interface control, multi-parameter storage. 5, energy detection mode, to ensure consistency of weld quality. 6, stepless adjustment of the amplitude without the need for frequent replacement amplifier. Ultrasonic metal welding application of products: 1, nickel oxide and nickel battery nickel screen films each melt. 2, lithium batteries, polymer batteries each melt copper and nickel films, aluminum foil and aluminum melting each other. 3, wires melt each other, forming a partial melt with more than each other.

4, wires and various electronic components, contacts, connectors, each melt. 5, various household appliances, automotive supplies, large-scale cooling block. 6, electromagnetic switches, non-fuse switch high current contact, dissimilar metal sheets of mutual melting. 7, the metal tube end sealing, cutting can be water, gas-tight.

Specifications: 20KHz-40KHz;

Usage: apply to lithium batteries very film, dielectric capacitors, relays, transistors, electrical terminals, thermocouples, silicon components, refrigeration, etc. welding. Ultrasonic metal welding is an efficient, highly reliable welding method.

Features:

(1), two overlapping objects were welded by ultrasonic vibration pressure synthesis of solid-state take the form of bonding time is short, and the bonding part of the cast does not produce Organization (rough surface) defects.

(2), ultrasonic welding and resistance welding method of comparison, long life molds, mold repair and replacement less time, and easy to automate.

(3), the same kinds of metal between the different kinds of metals may be ultrasonic welding, and the Electric Welding much less than the energy-consuming.

(4), ultrasonic welding, compared with other bonding require less pressure, and the variant volume below 10%, while the cold welding the workpiece deformation amounted to 40% -90%.

(5), unlike other welding ultrasonic welding, as the requirements of the welded surface pretreatment and post-treatment after welding.

(6), dealing with ultrasonic welding without flux, metal fillers, external factors such as the external heating.

(7), ultrasonic welding material can minimize the effect of temperature (the temperature of weld zone does not exceed the absolute melting temperature of the welded metal 50%), so as not to make structural changes in metals, so it is suitable for electronic applications in the field of welding.

Figure Ultrasonic Assembly systems

|